Sup Y’all?

We Started a New Batch of Cider!

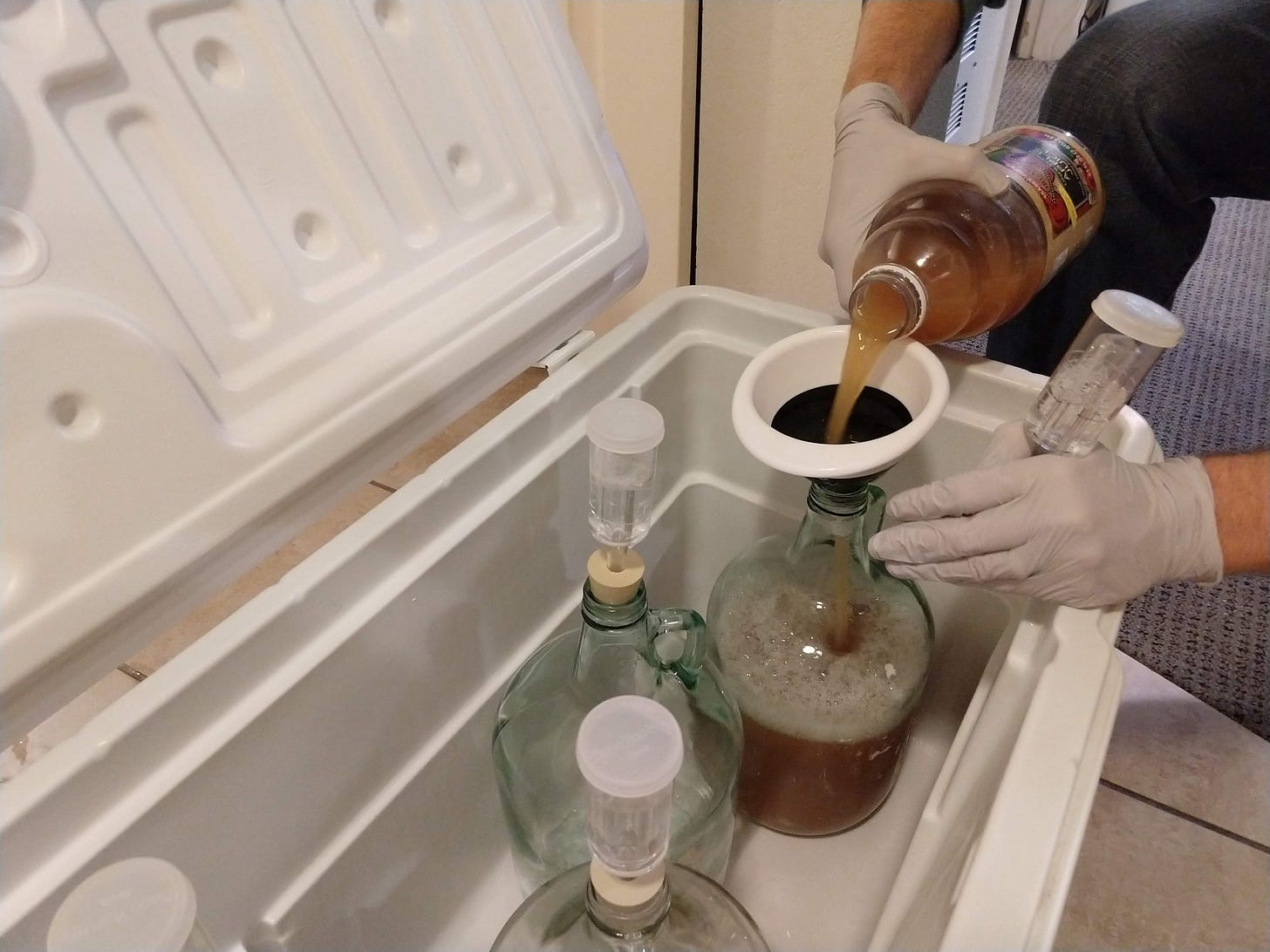

Ah, isn’t it cute? The yeast are already hungry little buggers eating all the sugar and producing liquid joy.

How’s It Made?

Fast history/explanation on cider. Americans used to guzzle it. At our founding until prohibition, people drank cider like water because it was safer than water and usually had a pretty low alcohol content. Everyone who lived on a farm made their own. They pressed a bunch of apples from varieties that were small and tart (crab apples), put the juice in a bucket and let it sit. The yeast (micro organisms on the apple skins) ate the sugars in the juice and turned it into alcohol. This is called a “wild fermentation” where you don’t control the process, the yeast is unknown making every batch different. Cider made this way is called scrumpy. Prohibition virtually destroyed the tradition and all the farmers switched from growing types of trees that made delicious cider to trees that made delicious eating apples.

What’d We Use?

Trader Joe’s organic unfiltered, not from concentrate apple juice. Sometimes we use Columbia Gorge Organic Cider (that’s our favorite) but the groceries don’t have it in bulk yet. The nice thing about Trader Joe’s apple juice is it’s significantly cheaper so it’s great for experimental flavors.

Why Not Press Our Own Apple Juice?

I know, right? That was the way we planned on doing it back in 2010. We were really, really, really broke at the time which meant instead of buying a press we needed to make one. Online we found videos (BUT NO PLANS) where crafty and skilled people made apple presses using a carjack.

I don’t own tools, I took a wood shop class once in high school, that’s it. We had to beg a friend renting a space below the coffee shop I worked at if we could have some time with his tools, oh, and this is after we spent the day busing (cause no car) to no-man’s land just to get some wood we didn’t even know how to pick out, walk what felt like miles back to the nearest bus stop dragging this stuff and sitting with it all the way back on the bus. So by the time we are alone with my friend’s tools, we are hungry and cranky. I learned that, oh my gosh, drilling holes in the correct spot without a worksheet is not really that easy for the non-experienced. But we get this ridiculous looking thing back to our apartment just to realize the next day how many apples we are going to need in order to press a gallon of juice.💰This is not a hobby for broke people. Chris, being the experimenter he is, goes “This batch isn’t even going to work out. Let’s not buy apples just to mess up learning how to ferment. Let’s buy really cheap juice until we know how to make cider correctly.” So that’s what we did.

Green rag on window sill is to soak up rain water. Was “fixed” twice, and when it rained hard literally buckets of water poured into our kitchen.

“Going back to our roots.” That was a cheesy slogan we thought of as we imagined crushing apples, pressing them, fermenting it, and hand labeling elegant bottles, just like the pre-prohibition farmers. It sounds romantic and lovely until we opened our eyes and remembered that we live here, in Seattle, a modern city. Bringing the farm here is costly. For the customer. For the environment. For our backs. And it’s not who we are (see above making of press). Our backgrounds are in creative activities, art and science. What we love about the product is sitting in the bar and drinking it, and a lower price tag makes that more enjoyable.🍻

We started thinking what pressing our own cider would entail, picturing large trucks full of apples coming in. We would work day and night to poorly process it into some juice and then ship out large trucks full of apple scrap. The apple trees we’d use couldn’t make up the difference in this carbon footprint we just made… Or there are large juice companies right next to the orchards that will use million dollar machines to process the apples twice as efficiently as most cideries can. Picture a much smaller truck arriving with the same juice, no second trip to remove waste.

What are the Downsides of Receiving Juice Instead of Apples?

Less options for juice from traditional hard cider apples. This means our juice will be less complex. What can we do about that? Over the years of testing, we think we’ve hit on a few tricks. Our whole mission is to create complex, delicious cider out of relatively cheap organic apple juice that this state has a ton of. All we have to do is add ingredients that create a complexity that is missing. That way people can enjoy a good for the environment, affordable, but delicious and totally satisfying product.

Yeast

We aren’t making scrumpy, we are trying to control the final product as much as possible so we add our own yeast. There are hundreds of yeast strains to choose from. We tried, let’s see… a lot. Chris was having a good time experimenting with new ones, and they really did create ciders that taste different from each other. I made him stop. We use one right now that really works for us and makes a product we think tastes great, so as fun as experimentation is, we could be in the yeast selection phase forever if we tried to test them all.

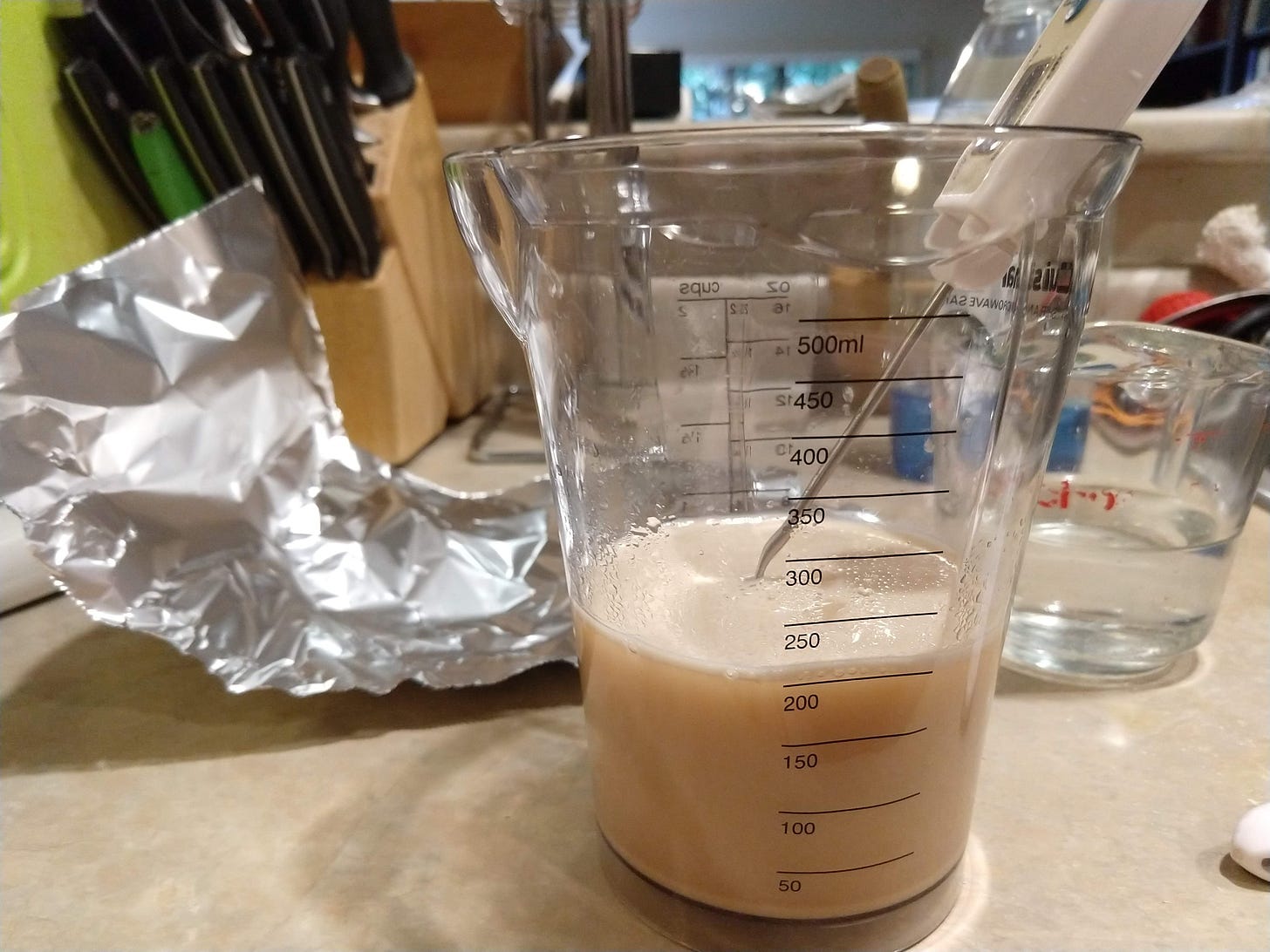

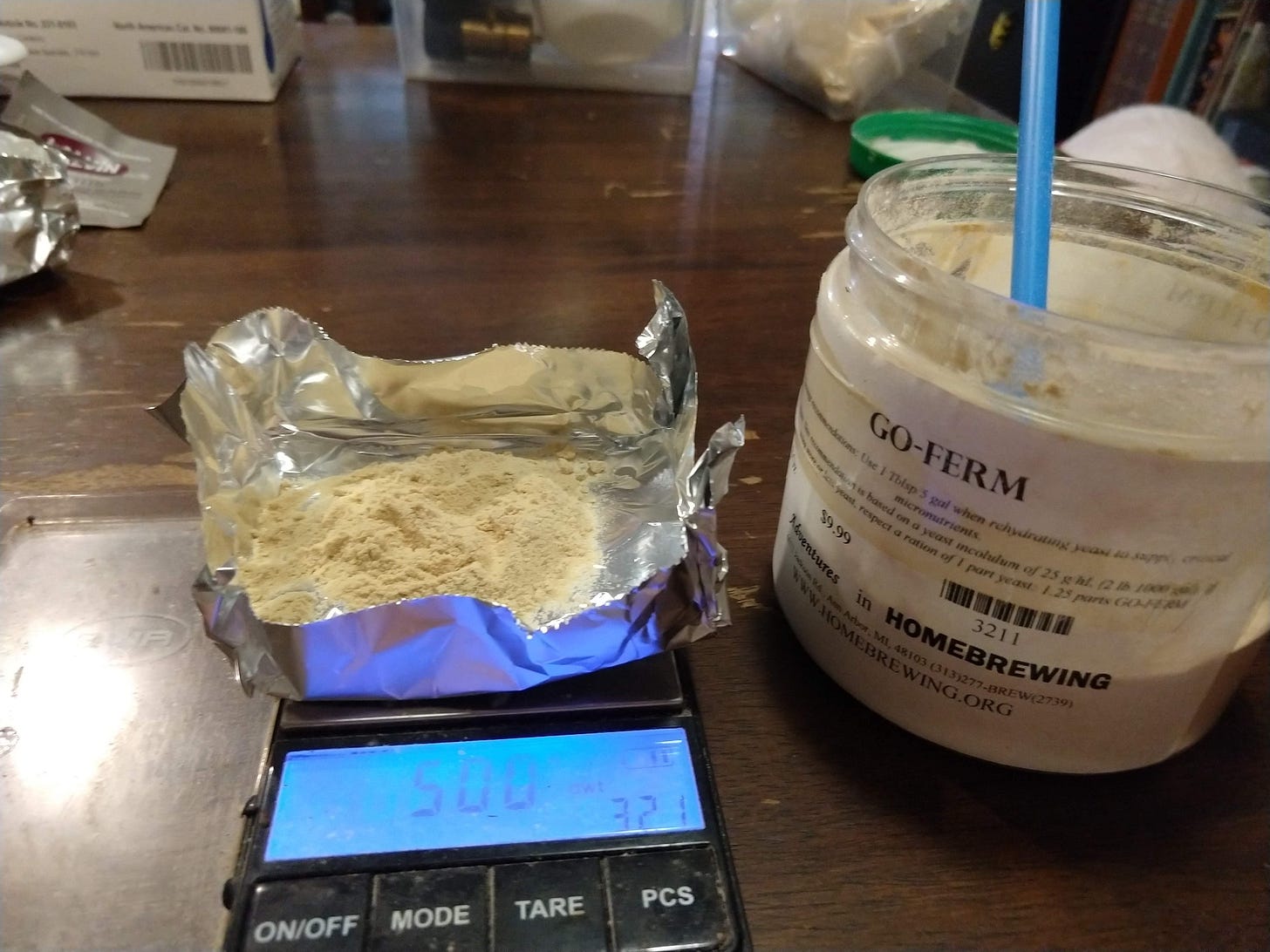

Did you know yeast is similar to a tiny animal? I didn’t. Our first few batches did not taste very good, and we learned that yeast, just like people, need to eat a balanced diet or they become sick and cranky. Our yeast only had a diet of sugar so they gave off some unpleasant flavors. To help them out, we now add a few different vitamins at different intervals throughout the fermentation process and we also add nutritional yeast (dead yeast). Allowing our yeast to become cannibals improved our cider drastically.

Oxygen

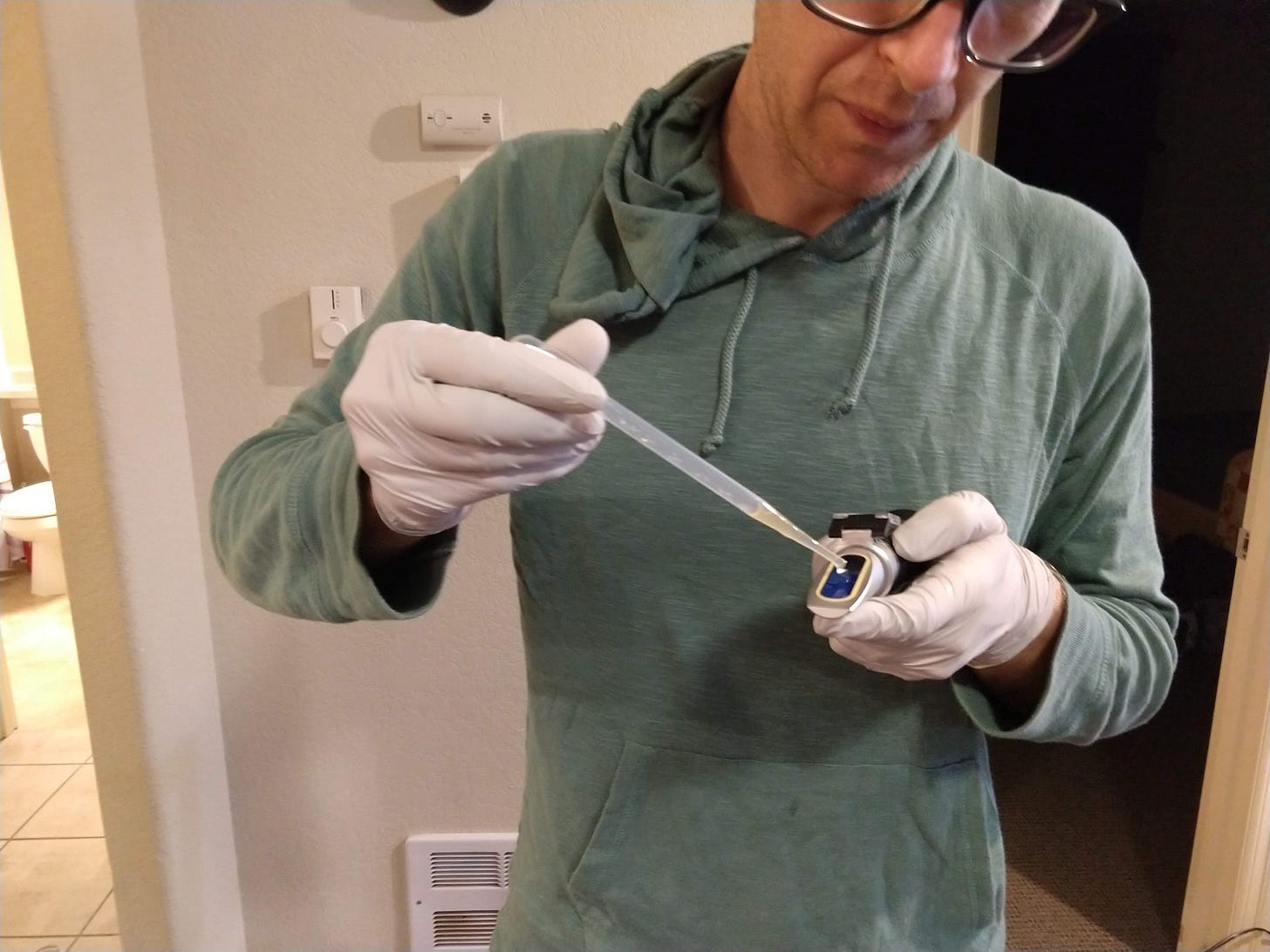

We add pure oxygen from a tank forced through a special rock with minute little holes in it. This way, super fine bubbles are made and by swirling it in our juice the yeast can develop a thick skin to keep out their alcohol excretions. In general, we are making their lives a little happier making our product extra tasty.

On the Business Side💳

We have chosen our merchant service provider! Dund-da-da-done - Dharma! They seem not only the least shady, but possibly even an ethical company. They are certified green and donate a percent of their profits to charity every year. Researching this was a painful but necessary experience. When we have a taproom we will want to accept credit and debit cards. Not cats.

In order to do this we need a merchant service provider that will take the credit card information and give it to the bank. Square is an example. How a business is charged for this service varies between providers. We ran some numbers guessing what the average customer bill will be and how much we will process per month. It helped narrow down our merchant service options. The disgusting truth is that what the provider charges you is a small fraction of what the bank will. Banks charge you what’s called interchange. Interchange equals a percent of the item price, plus a certain number of cents, all dependent on the type of card being swiped (don’t worry, your rewards are paid for one way or another). For instance, visa signature: 2.3% + $0.10, so a five dollar purchase = $0.22. What the?!!! That’s before the merchant provider charges its monthly fees and mark-ups. Why did we bail out the banks again? It shouldn’t cost more to process a $30 transaction than a $0.50, it’s all automated anyway! So if you wonder why things are so pricey you can just glare at that bank on the corner. 🏦😡

Next - Up

Watch Cider

The yeast needs about 10 days to convert all the sugar. During that time we will need to keep the product cold (our yeast strain works best under 60 degrees) and we will need to periodically feed the yeast as well as add a special secret ingredient. (If you are interested, ask me, I just didn’t want it blurted out on the internet.)

Work More on the Plan

I’ve already looked into large local organic apple juice producers and I have one I want, but I haven’t had the courage to ask them to supply us yet. I need to get a hold of them and ask if they could produce enough of what we need, get it to us, and what that might cost us. This means I want to look one more time at the numbers and see how believable they are. We had to guess how much people drink with how many seats we think we can fill. The numbers just look really optimistic. I’m like, really, that’s a lot of cider. I don’t want to be wrong by truckloads, I want the budget to be real.

Cider Week

We went to the Cider Summit. Had a great time. We drank some really fantastic ciders, our favorites were:

Snowdrift - They are an orchard in East Wenatchee, no need to tell you specific types, I have never had a cider from these folks that wasn’t spot on.

Archibald James - Wow, this was a fun surprise. They are brand, brand new from Cashmere WA. Very traditional, delicious, laboriously crafted cider.

Bauman’s Cider Company - All the ciders at this table were amazing but they are legendary for Loganberry. You can’t buy their stuff in Washington yet but it sounds like it’s all over Portland. They are from Gervais, Oregan.

French Cider - Joan Harkins always has a table at these things and we make sure to hit her table early. She travels to France every year and finds the best ciders. She imports and distributes them here, which you can order from her website.

Lastly, we tried going to what The Stranger said was to be a 2 Towns cider tasting at Chuck’s Hop Shop, and nobody knew what I was talking about. They even made sure it wasn’t happening at the other store. So, I guess cider really hasn’t had its 15 minutes of fame yet, it’s waiting on us.😊 We did have a good time though, they had some nice ciders on tap, but a word to the wise they have some really great stuff in bottles in the fridge. I really enjoyed the Blossom Nectar from Tieton.

We love feedback of any kind, and hi’s are always nice.

Previous Newsletter: Cider’s Having It’s Yearly 15 Min of Fame

First Newsletter: Our hobby’s putting on big kid pants