Happy Spice Time Pumpkin People!

Seen any good Halloween decorations? The other day I saw a 7ft dog skeleton on someone’s porch. I don’t know that I’m going to see anything to top that.

Fall is also cider festival time, and we recently went to Cider Swig in Tacoma. There’s a bunch of good ones, but the timing worked out and this is one of my favorites. It’s always crazy how different each year is, how many new cideries there are to check out, and this year, there was a lot of networking to do. The guy we’ll probably work with to make cider for pop-ups (who I’ve been calling The Facilitator) was there with his ciders. It was nice to check back in, he’s going to be pretty busy with fall pressing and fermenting, but sounds like we could get squeezed-in in another month or two. And in the meantime, we might be able to get some experience with the process helping other makers. Just got to keep reminding him.

The New Cider Guys (the guys we met who worked with The Facilitator to get started) also had a table. They are doing so well! They’re super busy and popular and their cider slushies were a hit at a Pike Place Market event last month. I think we’ll be able to help them out when they start a canning run soon.

The highlight though, was when we were checking out a new cidery’s table and, surprise! The guy pouring our tastes was Chris’s old soccer teammate! He’d moved away a number of years ago, but now he’s working for a local cidery. Chris started sharing our plans with him, so he was like, “hold-up, let me get the boss” and grabbed the cider owner, and we got a chance to chat with him for a long time. Asking what starting up was like, he said he went the investor route. It took him about a year to find enough folks willing to wait, maybe as much as eight years, before really seeing a large return on their investment. His business model is pretty much the direct opposite of ours and it’s a tricky way to go. He wants to become a nation wide distributor, and right now, he still doesn’t make his own cider. He’s contracting it out, so sending the recipe to large makers and buying the cider from them. It really decreases the start-up costs but he has to worry about his recipes getting stolen. (You have contracts signed that they won’t steal your direct recipes but you can’t help them taking the overall flavor idea.) Chris and I worry about this too, making cider for a pop-up, folks are going to know exactly how we make it. Once he’s paid for it, he then takes the cider and sells it to bars and stores and he doesn’t have his own taproom yet.

He loves our business model. He confirmed all our previous thoughts on profit margins. The price he sells a keg to a bar is about $200, and then the bar will make $1,000 selling that keg glass by glass to customers. There are a lot of costs and energy that goes into running a taproom, but there’s a lot of reward if you can do it. (Besides, I think it’ll be the more exciting option.)

His company isn’t profitable yet and it’s between one and two years old. But, he’s doing business and it’s likely profits are not far down the road. He thinks it’ll help a lot to get his own taproom.

I asked him about locations, because the build-out for a building is going to be our biggest expense. Generally, if we can find what’s called a “turn-key” location, a place that was a similar business so a lot of the build-out is already done, you can save a lot of money. These types of spaces have worried me a little though, because if the previous business didn’t succeed, my thought was, can we? Is the neighborhood not a good fit for this type of business? He said it’s probably not worth worrying about, that it’ll probably be a brewery and the beer market is just over-saturated. However, what is worth worrying about is the condition of the building. Sometimes their build-out was flawed to begin with and that’s why they finally gave up. So there can be a lot of costs in what feels like a too-good-to-be-true situation.

We got his contact info and he’ll be a great resource going forward. Especially if and when we start the process of private investors.

Costs Of Working With The Facilitator

In order to gain experience and prove that there is a market for our cider we’re planning on hosting pop-up tasting events. We’ll have to make it at a licensed facility and pay to use someone else’s equipment. The man I’m calling The Facilitator is thankfully willing to provide both for a reasonsible fee.

But there’s a large number of costs associated with this so I did a little number crunching to see what the bill might be.

The Facilitator’s Time: X per hour (I have a number, just don’t think he’d want it posted on the internet)

The Facilitator’s % of Sales: we’ll probably give the cider away for free to the bar, so instead we’ll have to pay him more per hour

Apple Juice: Smallest amount we can ferment with The Facilitator’s equipment is 10 bbl, about 310 gallons. That’s around $1,900 for juice including shipping.

Yeast: $80

Keg Rental: We’ll probably do the pay per fill method of keg renting. 310 gallons is about 18 half bbl kegs, costing $400.

Transportation: The kegs will need to be moved from the facility to the pop-up. Truck rentals will be a nightmare until after Christmas, so a better option maybe to use Taskrabbit. No idea the price but I’d imagine it’s fair.

Brew Kettle: The Facilitator doesn’t have one of these and our current process requires it. But what exactly we need really depends on how our latest test at home goes. If we can make an extract, and filter, and it turns out tasty, we’re looking at spending maybe $300 on a small kettle. If it doesn’t turn out and we stick to our original process, we’ll need to buy a 2 bbl electric brew kettle: $3,000-$4,000. More on this later.

Accountant

Since it looks like we’re going to start spending some more money than we’re used to and acting like a legit business, it’s time for an accountant. Especially 'cause big brother Gov really likes everything declared and his special cut.

We had a meeting with Ms. Bean Counter (I’m trying to keep everyone anonymous) that The Banker recommended to us. She was super high-energy and gave a lot of information. Although some of her advice sounded a little out-dated to me, she has an amazing amount of experience, and she seems exceptionally capable. She didn’t seem to get our business model right away, she talked a lot about getting that one item on the shelf, but she was enthusiastic and has a massive catalog of companies she has saved by cleaning up their horrendously kept books. I don’t think she knows a lot about cider and the specific tax rules around it, but it’s an eventuality we’ll have to hire a lawyer that specializes in alcohol anyway. Most importantly, her price tag also seems out-dated.

Financing

I had a few meetings with a loan coordinator. The good news is, we fit right in their target market. I think mostly for location, but I answered a lot of questions and she implied we fit perfectly for a number of reasons. The issue is that although we have some capital to invest, we don’t have any assets, so certain loans are out. Equipment loans, are again relatively easy to secure because they are an asset in themselves. We might be able to get a 504 loan, but that will depend on the building upgrades we will need. A 7(a) loan might be doable as well, but that would depend as well.

She did mention a flex loan, that is still large, not large enough to cover the whole business, but in particular it might be useful now to fund the pop-ups. I haven’t applied for it yet, I was hoping to speak to our mentor and see if he thinks the rates are worth taking on.

The Advisor

I’ve spent a lot of time going through notes our advisor (a guy with a big background in the brewing operations) made to my business plan. Some of the notes call for clarifying, some for gathering more data, and some of his notes question our decisions on equipment, process, or even how we envision our business. It’s good. He’s doing exactly as we hoped. Our plan will be stronger after this.

I picked out just a couple notes to share. One is that he thought it would be useful to compare and contrast the breweries to cideries in the area. In Seattle there are 7 cideries with taprooms and there are 62 craft breweries. Sweet stat, huh? He also thought it would be a good idea to compare the cost savings of draft over packaging and how draft is also a more sustainable option. This is a great idea, but a task because there is so much that goes into canning, and price estimates are hard to find. What I could find, is what a mobile canner on average charges, because a lot of breweries don’t have a way to fill cans, the machinery is super expensive, so they pay a company to come out by truck with their equipment. The canner charges about $.40 per can not including:

label and all of its costs - graphic design, government label approval, printing and printing material

additional packaging material

cold storage

the mobile canner’s travel costs

lost cider during canning (average of 15% product loss)

shipping

the brewery’s labor

Selling directly to customers on draft, I have the total cost (not including expenses just direct costs) estimated at $.64 a glass. So if we only include the literal canner’s fee of $.40 a can, it will already increase our costs by 63%.

New Process Test

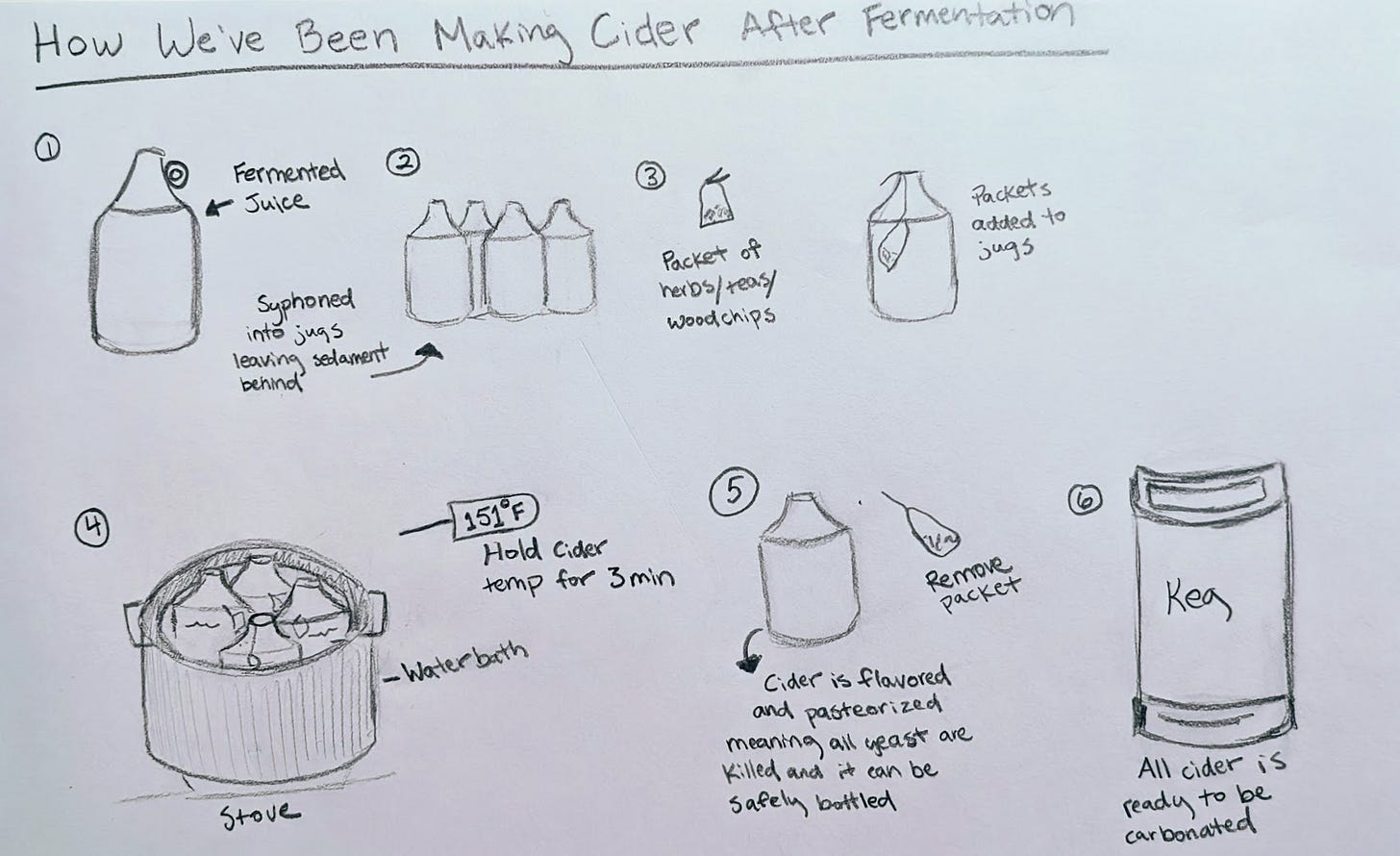

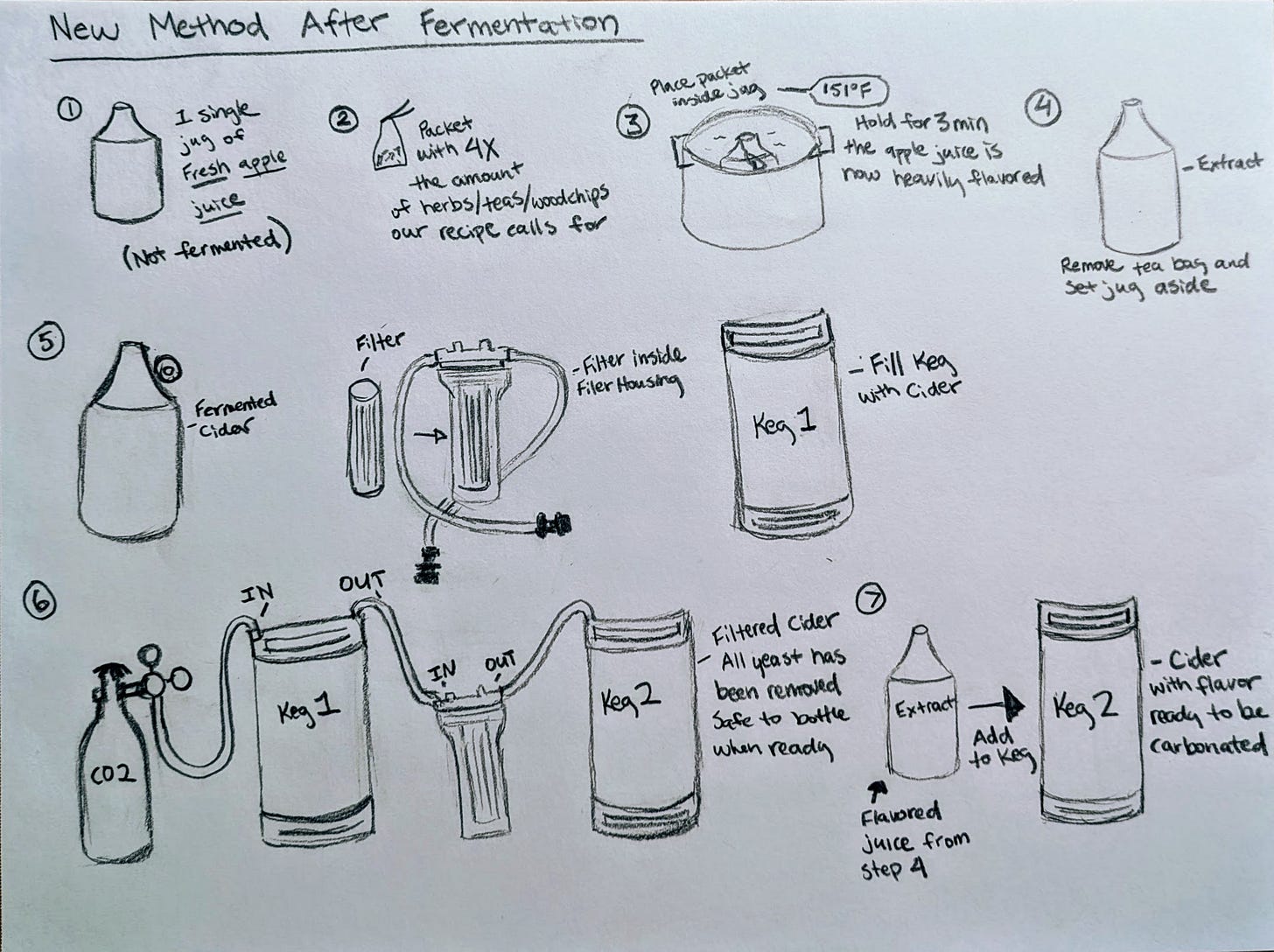

Before we work with The Facilitator, we need to run some tests at home. We have a step in our process that is a little unique to cider making. We heat our cider for a very short period of time before carbonating. Plenty of cideries have a version of this step, they just do it after bottling not before. (One cidery in Oregon used to throw their bottles in a hot tub.) Chris developed this step because, for making at home, this step is really dangerous. (Picture glass bottles exploding in our kitchen sink.) However, heat is not always necessary. But all cideries have to do something if they want to back-sweeten, meaning add fresh juice back at the end of fermentation, because that extra sugar will continue to ferment and explode the bottle, or if not bottling, will make a higher level of alcohol and not stay sweet. The vast majority filter their cider, removing all the yeast, in the hopes that when juice is added back nothing exists to change the sugar to alcohol and make CO2. Cideries typically heat the bottles or add velcorin to make sure the cider won’t change. Filters are expensive and Chris wanted cloudy cider anyway so we started heating it for 3 minutes before kegging. An unforeseen positive, and why I still want to keep doing it this way, is we believe it ages the cider. Mid-tier and higher-end cideries age their products for 6 months or so before selling. (That’s a lot of space to rent.) I think that quickly heating gives our cider a similar flavor without the wait. I also think this is the best way to add flavors like teas to the product. Otherwise, one ferment can only be one flavor, because it’s added during fermentation. Our plan is to make one big fermentation and divide into a few different types.

But, nobody does it this way, so if we want to work with The Facilitator to make our product, it would be easier to make it the way he does. Which means filter the product and possibly make an extract. He doesn’t make extracts, but heating one little amount of juice with enough tea for all the cider might give us the flavor that we’re used to and allow us to avoid buying a large brew kettle.

So we ordered a filter (everywhere was out) and we’ll start the test as soon as we can.

I made some sketches of what we do typically and what we are going to try, assuming I couldn’t describe this very well, hope it helps.

Business Networking Group

The bank we’ve been working with held a business networking group last week that we attended. There was a guest speaker and afterwards we were broken into groups to try and meet people and see if we could make useful connections. It was great, I met a man who has a successful cheesecake business. He has all kinds of amazing flavors and also makes gluten-free. Besides giving encouragement and advice, he also said he could make us gluten-free cheesecakes for our cider house. He even wants to make special cakes to pair with our flavors. (So excited!)

Chris talked with another banker who was very enthusiastic hearing our plan, and was relieved it wasn’t going to be a cidery with a restaurant, and said that there’s a lot to be desired in casual establishments. Mentioning a few local cideries as lacking in personality, and attention to the environment and the customer’s experience. (We definitely plan on providing something unique.) Chris also met an architect who specializes in sound design, so Chris told him how I planned on paying for sound buffer panels and nice speakers, and he said that there are a lot things you can do just in the layout of a space to prevent the need for buffers. This guy will be great when it comes time for build-out.

That’s all for now! We should be getting a pail of organic apple juice from the wholesale supplier soon and we can start testing out the new method against our old one. They will compete head to head in a high stakes battle for our future. Thanks as always for continuing along with us into the future as well, we appreciate it.

Previous Newsletter: Putting in the Miles